Products

Metall forming presses

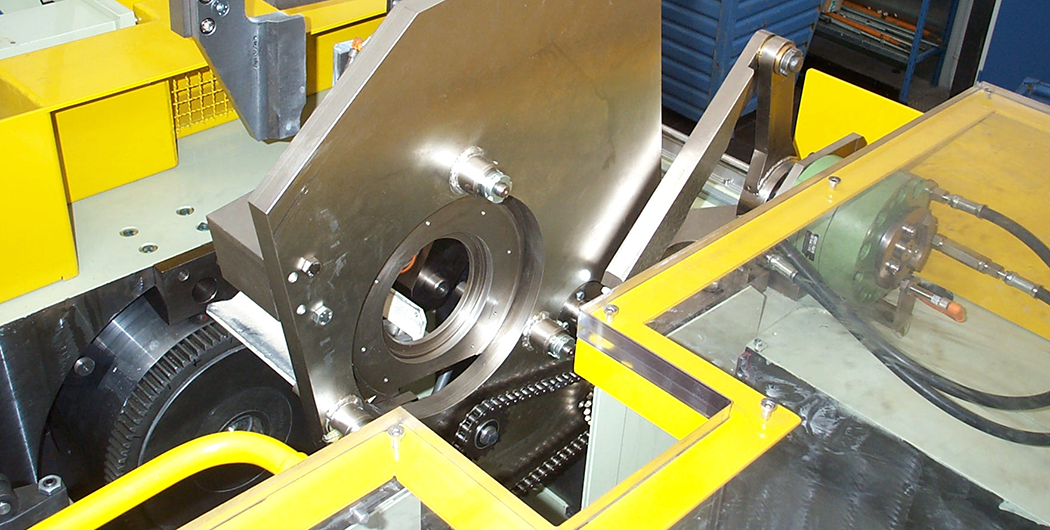

MF1600

MF1600

The perfect solution for smaller parts.

Technical data:

- Max. extruded length: 260 mm

- Max. stroke length: 400 mm

- Max. speed: 200 piece/min.

- Nominal press force: 1.600 kN

- Approx. net weight: 11.000 kg

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Automatic slug infeed system

Downloads & Media:

MF4000

MF4000

Combining power and speed in one machine.

Technical data:

- Max. extruded length: 275 mm

- Max. stroke length: 375 mm

- Max. speed: 200 piece/min.

- Nominal press force: 4.000 kN

- Approx. net weight: 17.000 kg

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Automatic slug infeed system

Downloads & Media:

MF4000.B

MF4000.B

Designed for high speed performance in the battery industry.

Technical data:

- Max. extruded length: 275 mm

- Max. stroke length: 380 mm

- Max. speed: 250 piece/min.

- Nominal press force: 4.000 kN

- Approx. net weight: 22.000 kg

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Automatic slug infeed system

Downloads & Media:

MF6000.B

MF6000.B

Unrivaled for larger battery parts.

Technical data:

- Max. extruded length: 325 mm

- Max. stroke length: 440 mm

- Max. speed: 180 piece/min.

- Nominal press force: 6.000 kN

- Approx. net weight: 31.000 kg

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Automatic slug infeed system

Downloads & Media:

MF10000

MF10000

If power is needed to do the job.

Technical data:

- Max. extruded length: 350 mm

- Max. stroke length: 450 mm

- Max. speed: 60 piece/min.

- Nominal press force: 10.000 kN

- Approx. net weight: 55.000 kg

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Automatic slug infeed system

Downloads & Media:

MF12000

MF12000

For the greatest challenges.

Technical data:

- Max. extruded length: 520 mm

- Max. stroke length: 675 mm

- Max. speed: 30 piece/min.

- Nominal press force: 12.000 kN

- Approx. net weight: 100.000 kg

Special features

- Sturdy frame, separate from the drive housing, for absorbing the extrusion loads; both parts made of spheroidal graphite iron

- Compact drive of the crankshaft via pneumatically controlled clutch-brake unit with spring loaded disc brake to allow controlled or immediate stops

- Speed-variable drive, creeping speed and facility for switching to reverse motion to facilitate the setting of the tooling

- Electromotive punch adjustment for correcting the bottom thickness during production

- Swing-off type slug feed and stripper frame of the take-off unit, resulting in short set-up times and simple size-part changes, optimized for high speed production

- Automatic permanent circulatory lubrication system with filter and offline filter system

- Take-off unit operating in absolute synchronism with the outfeed conveyor, ensuring trouble-free transfer of the products even in case of short extrusions and maximum stroke rates

- Automatic slug infeed system

Downloads & Media:

Markets

The market for technical parts consists of a great variety of different product designs and materials which leads to total individual request from our customers. Each impact extrusion press needs to be designed to fit special tooling requirements. With more than 100 years experience in the impact extrusion business and a sophisticated range of presses for the production of all kind of technical parts we are the preferred partner for our customers in the following industries:

- Automotive

- Engine building

- Pyrotechnic

- Electrical Engineering

- Home care